- Homepage

- Corporate

- Technical Service

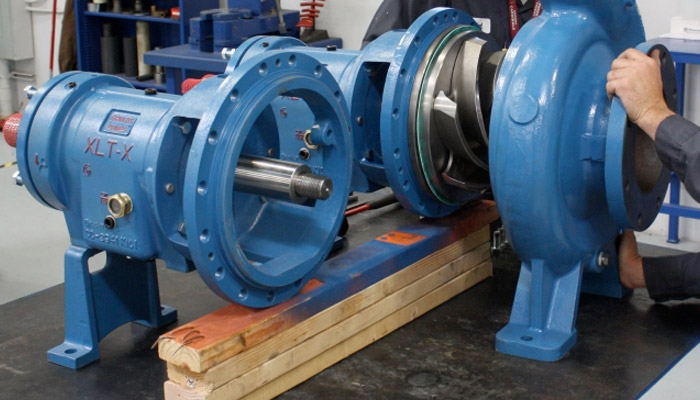

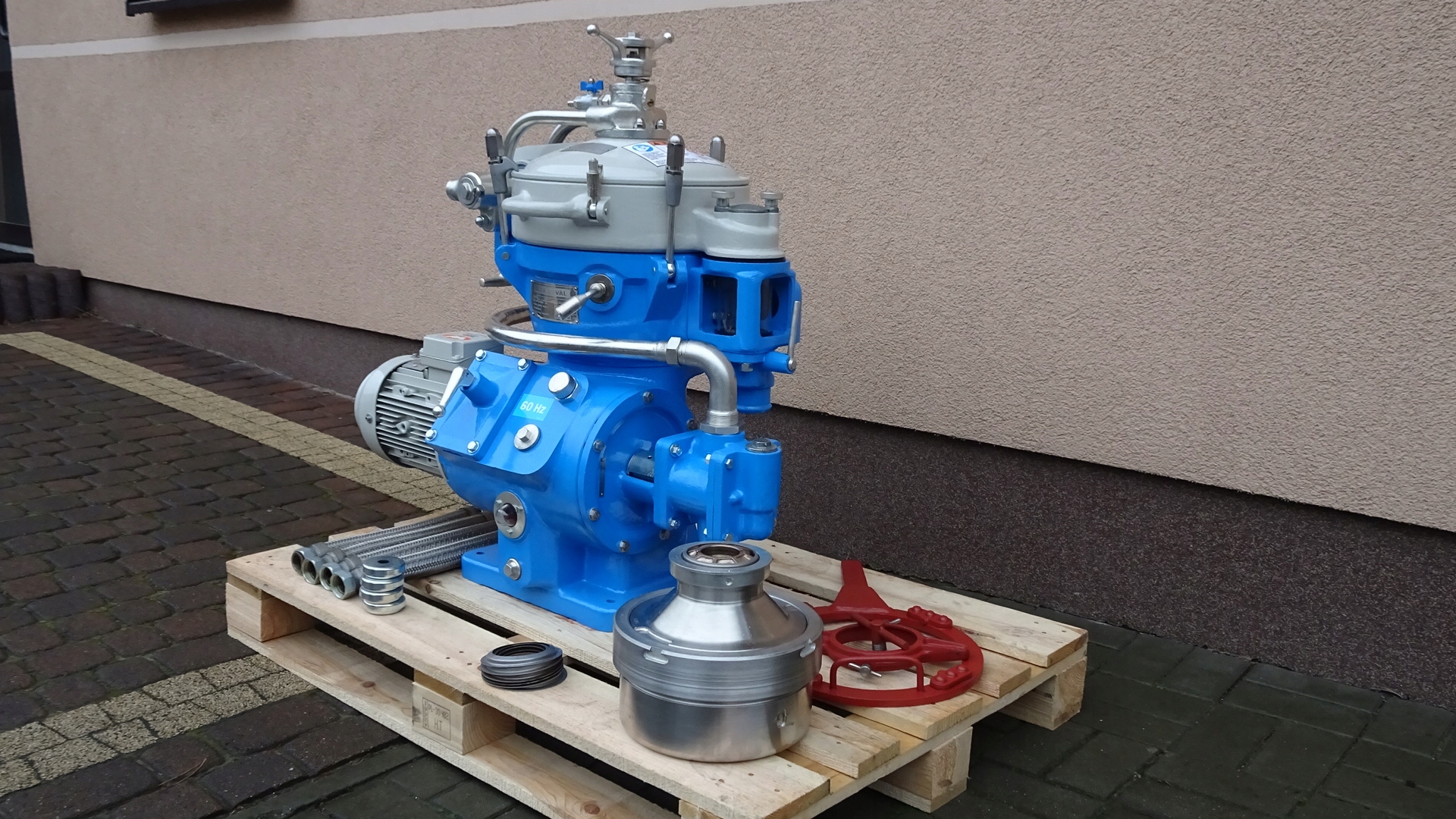

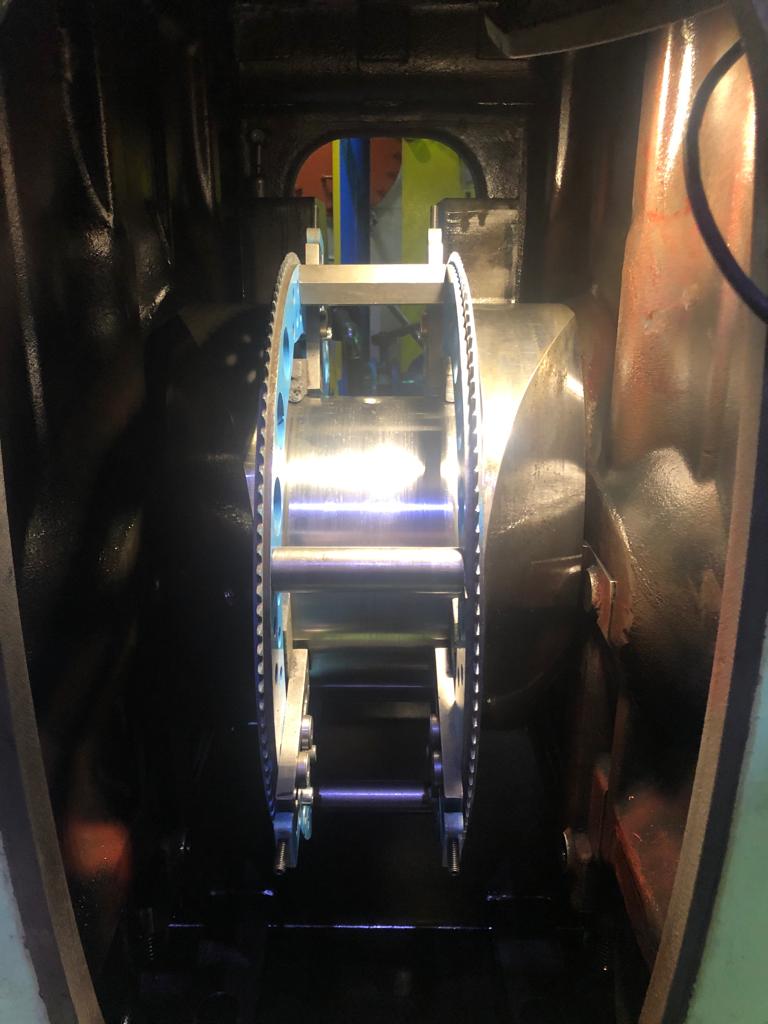

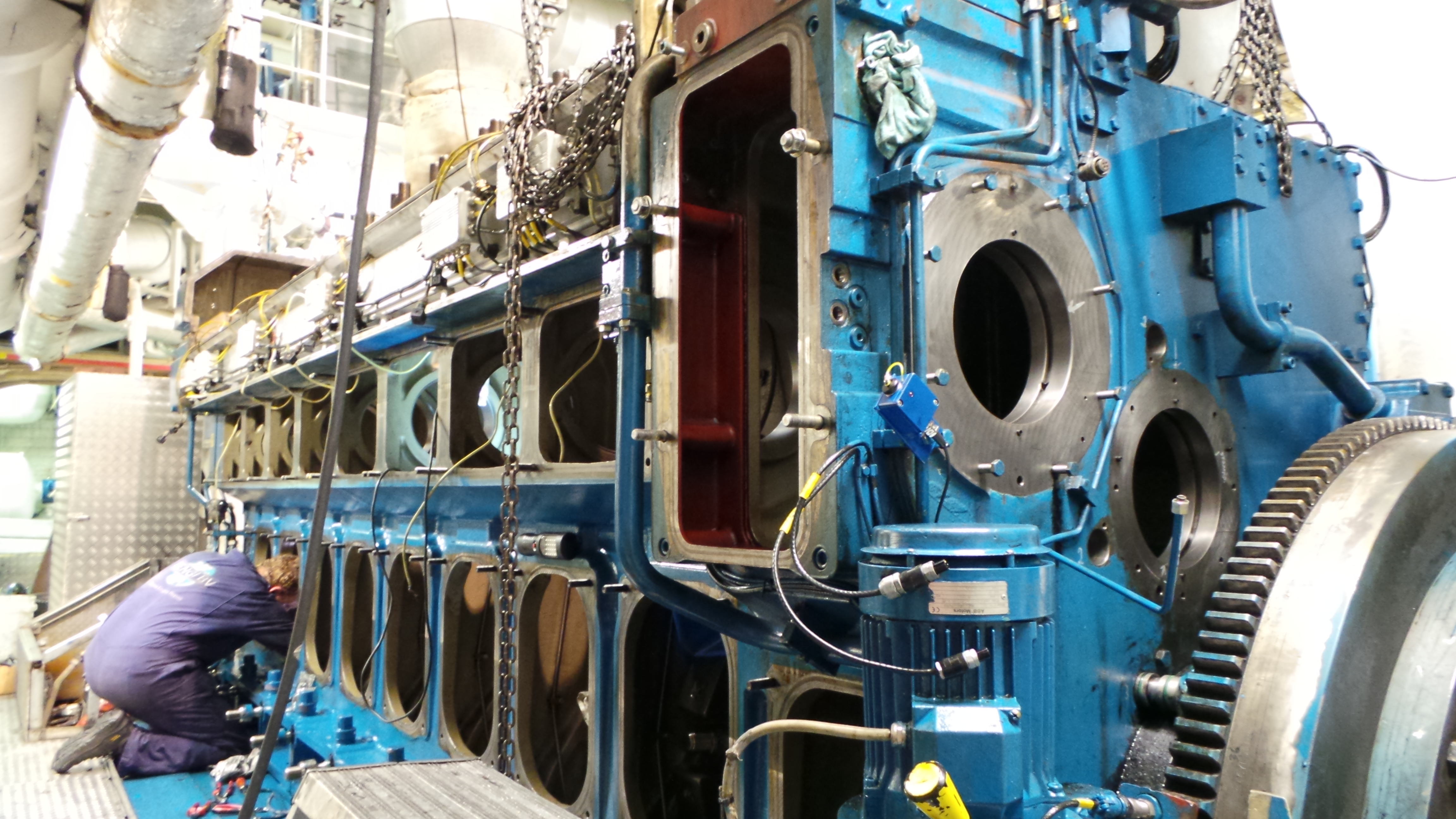

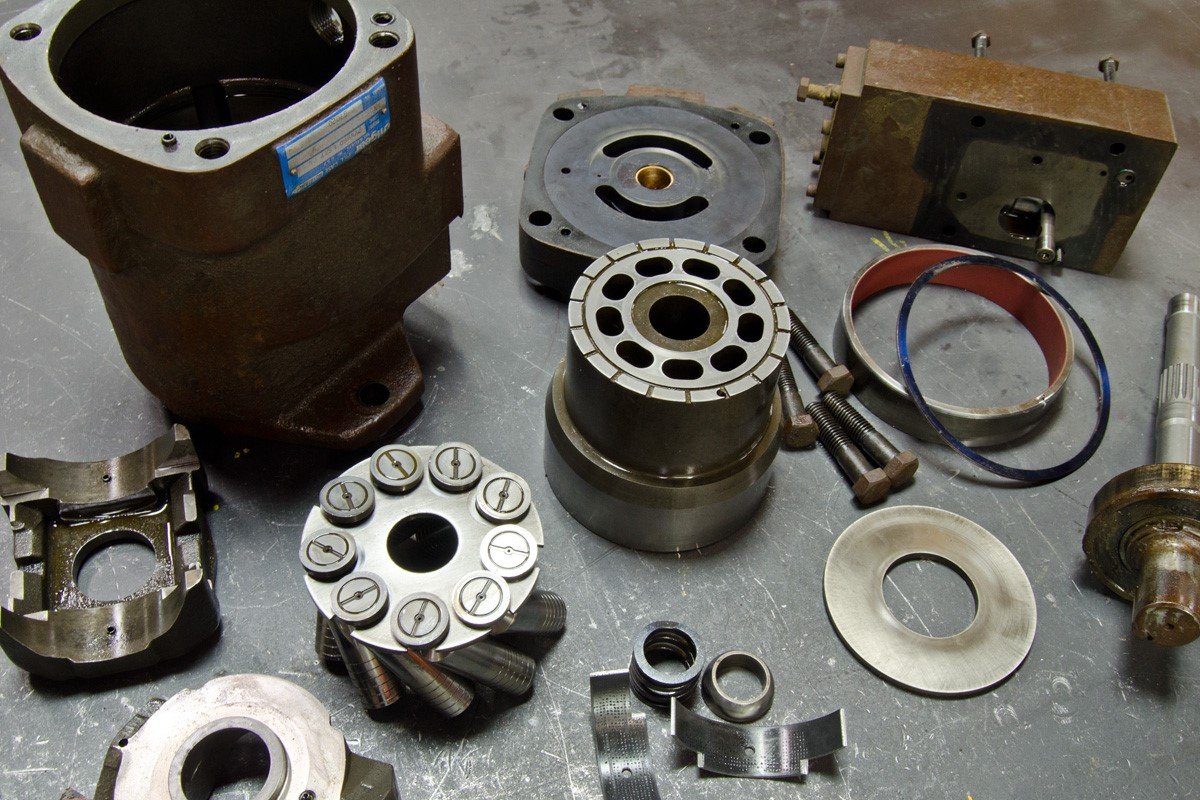

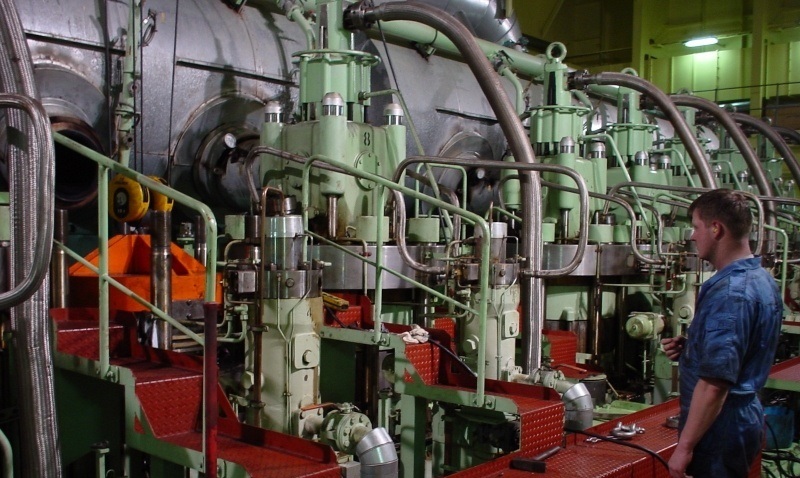

Mechanical Services

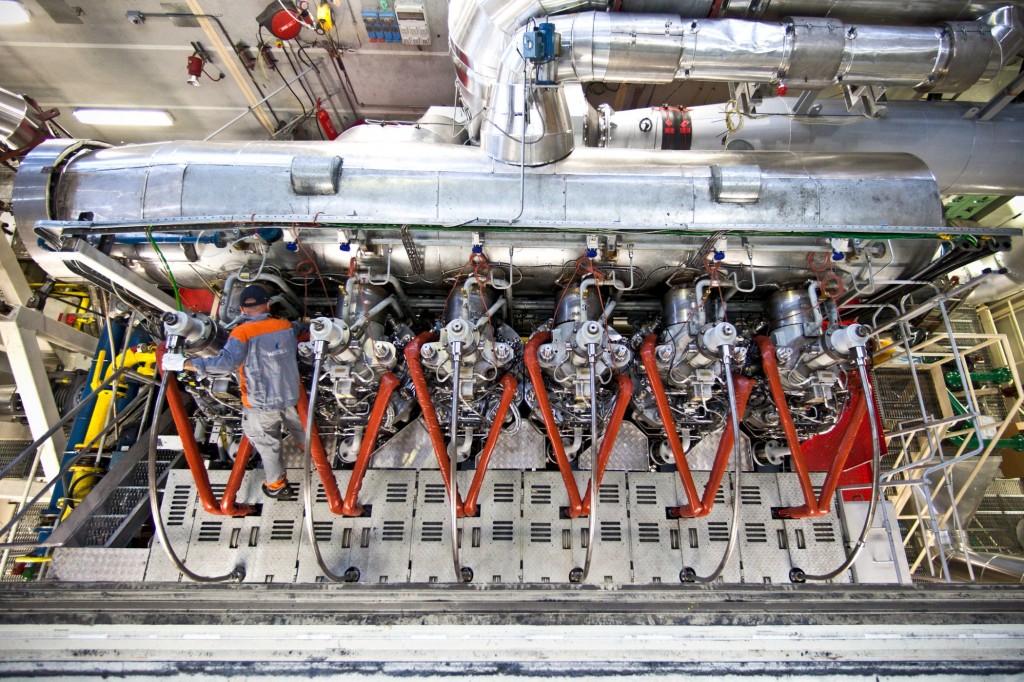

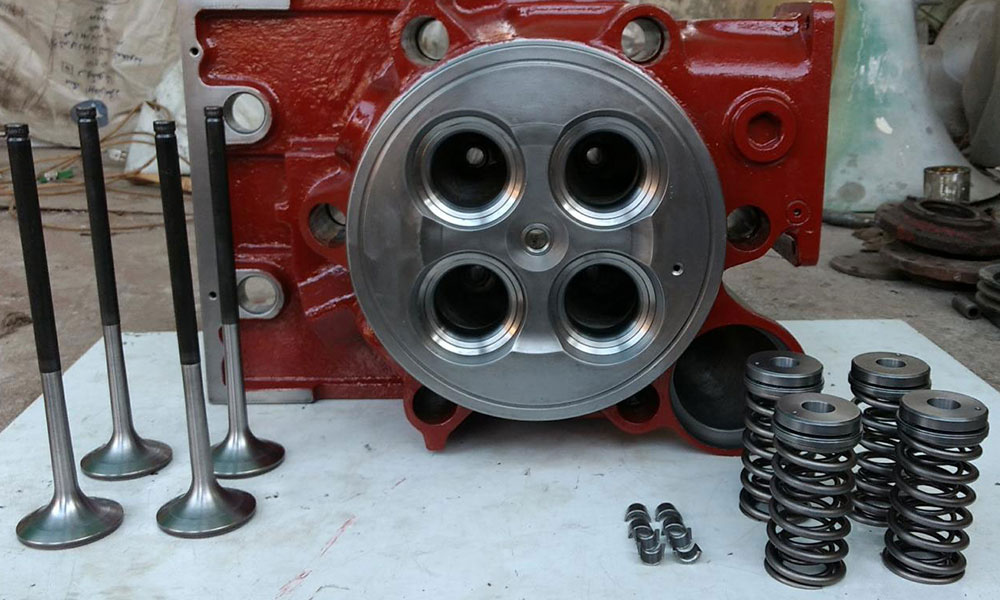

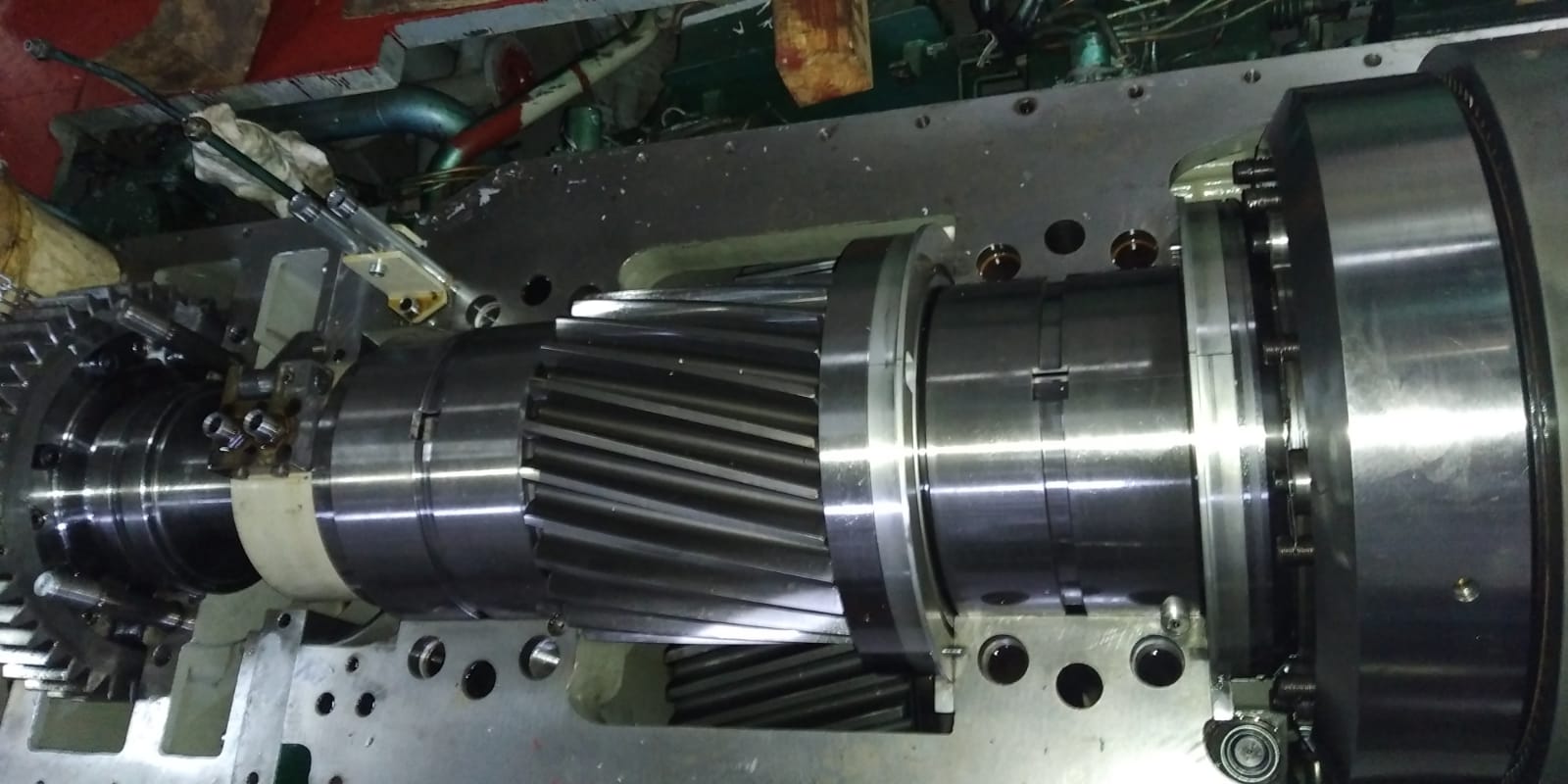

Engine Overhauling

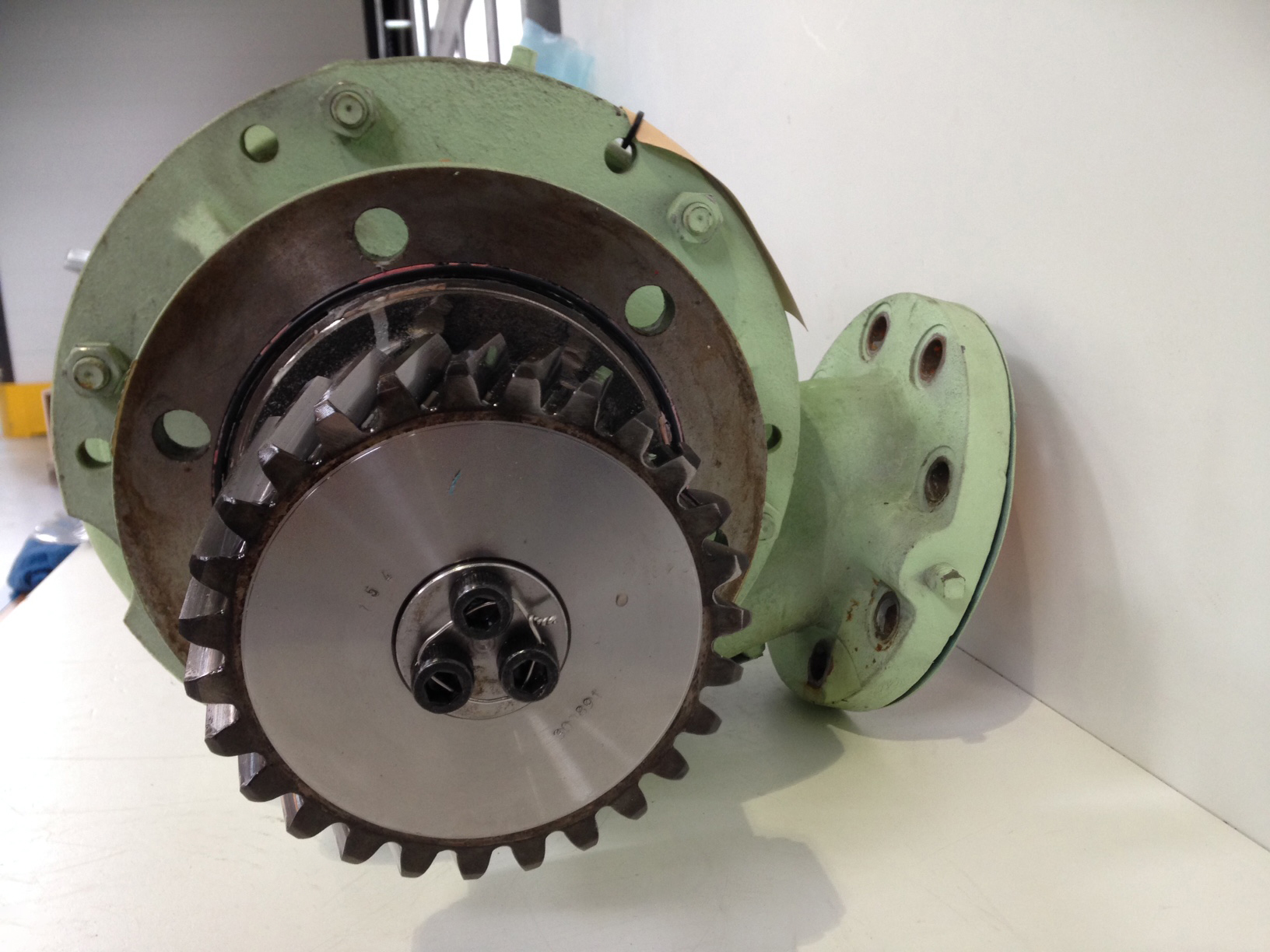

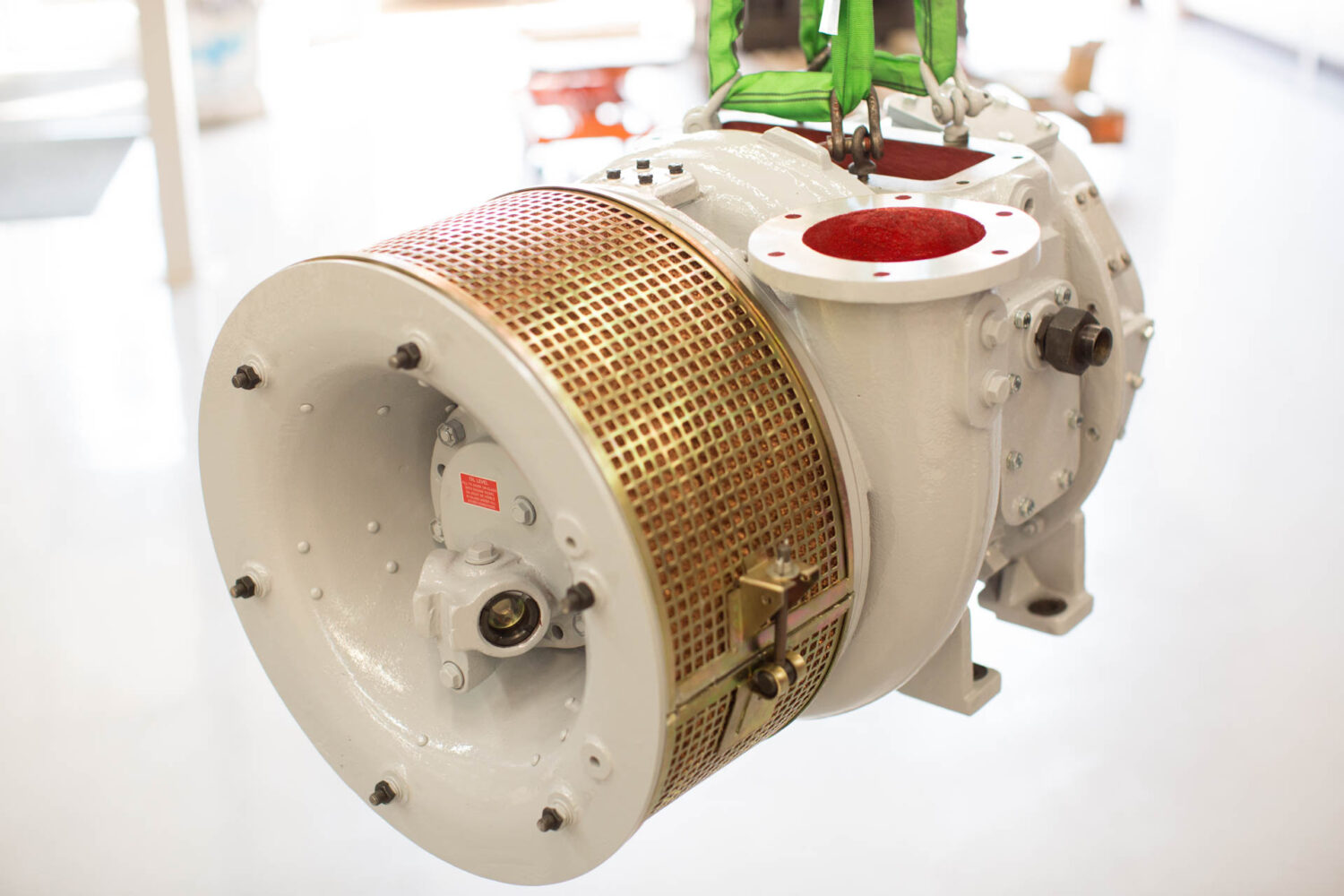

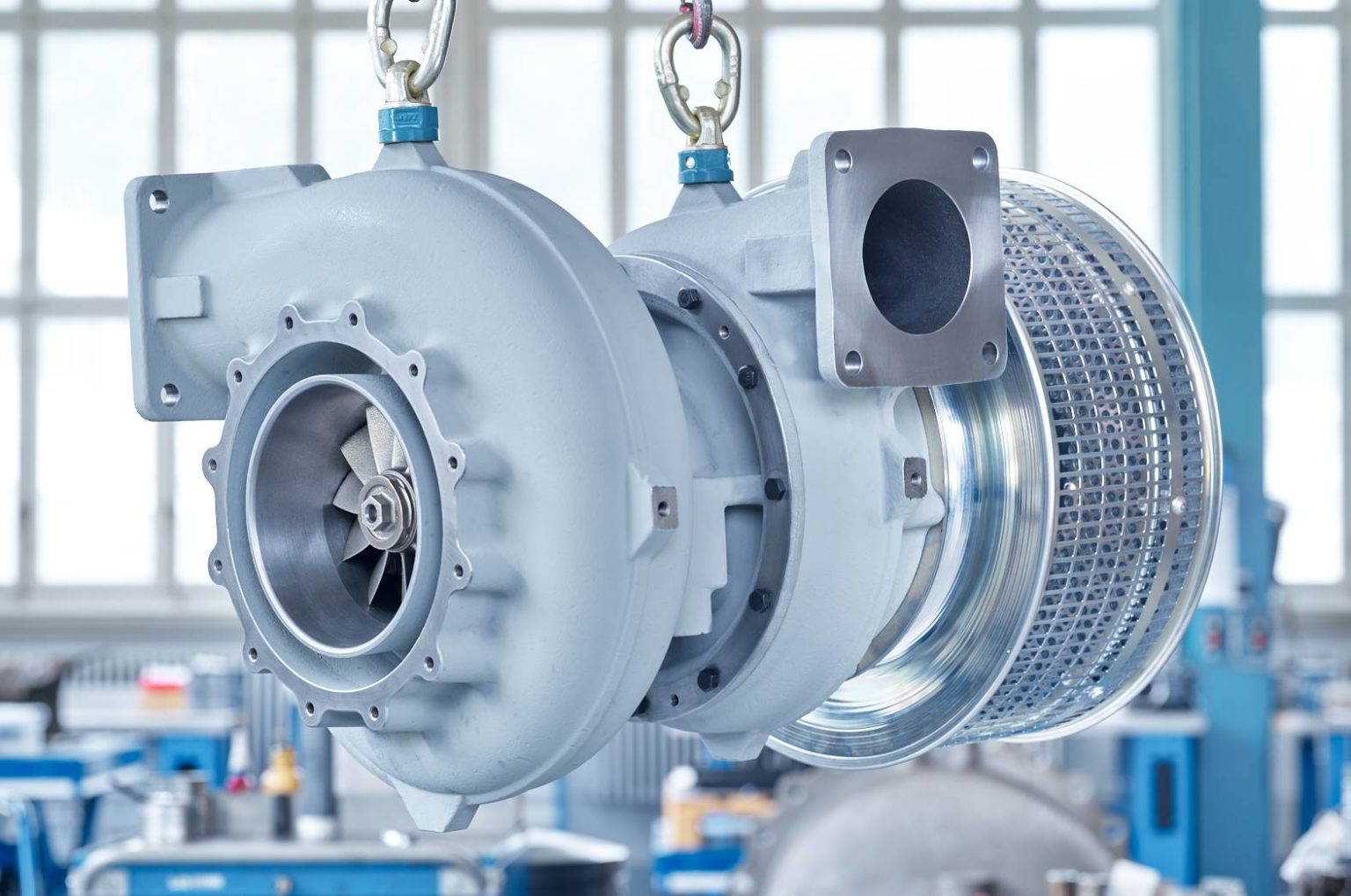

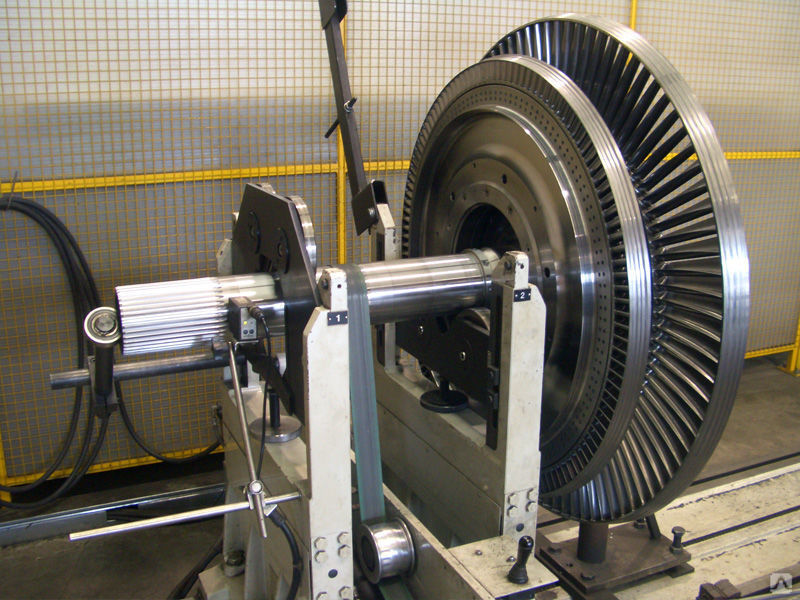

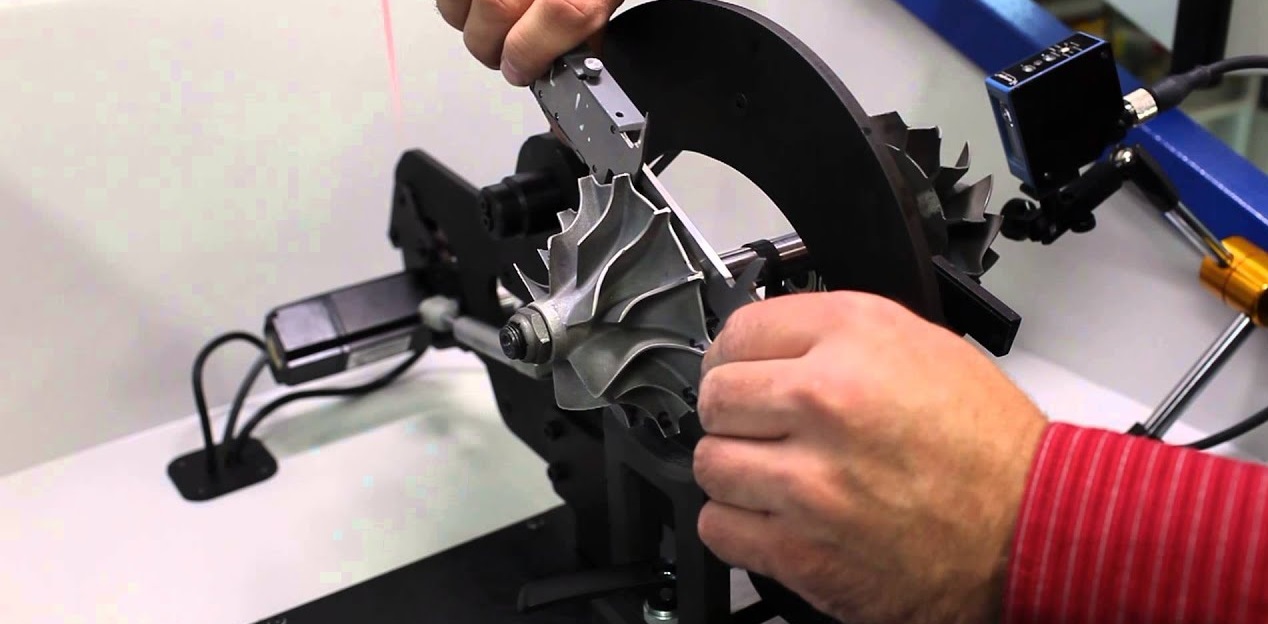

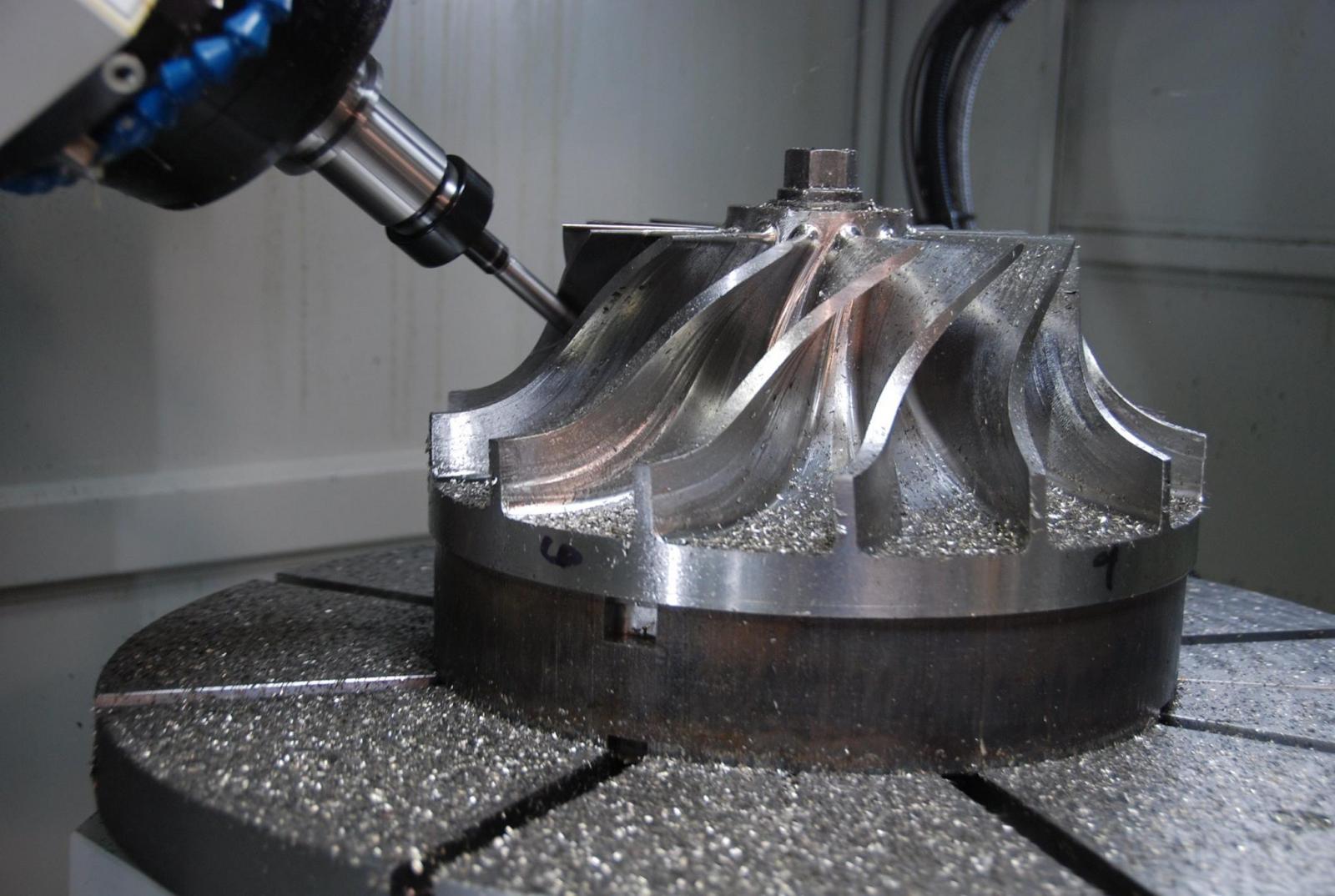

Turbocharging Services

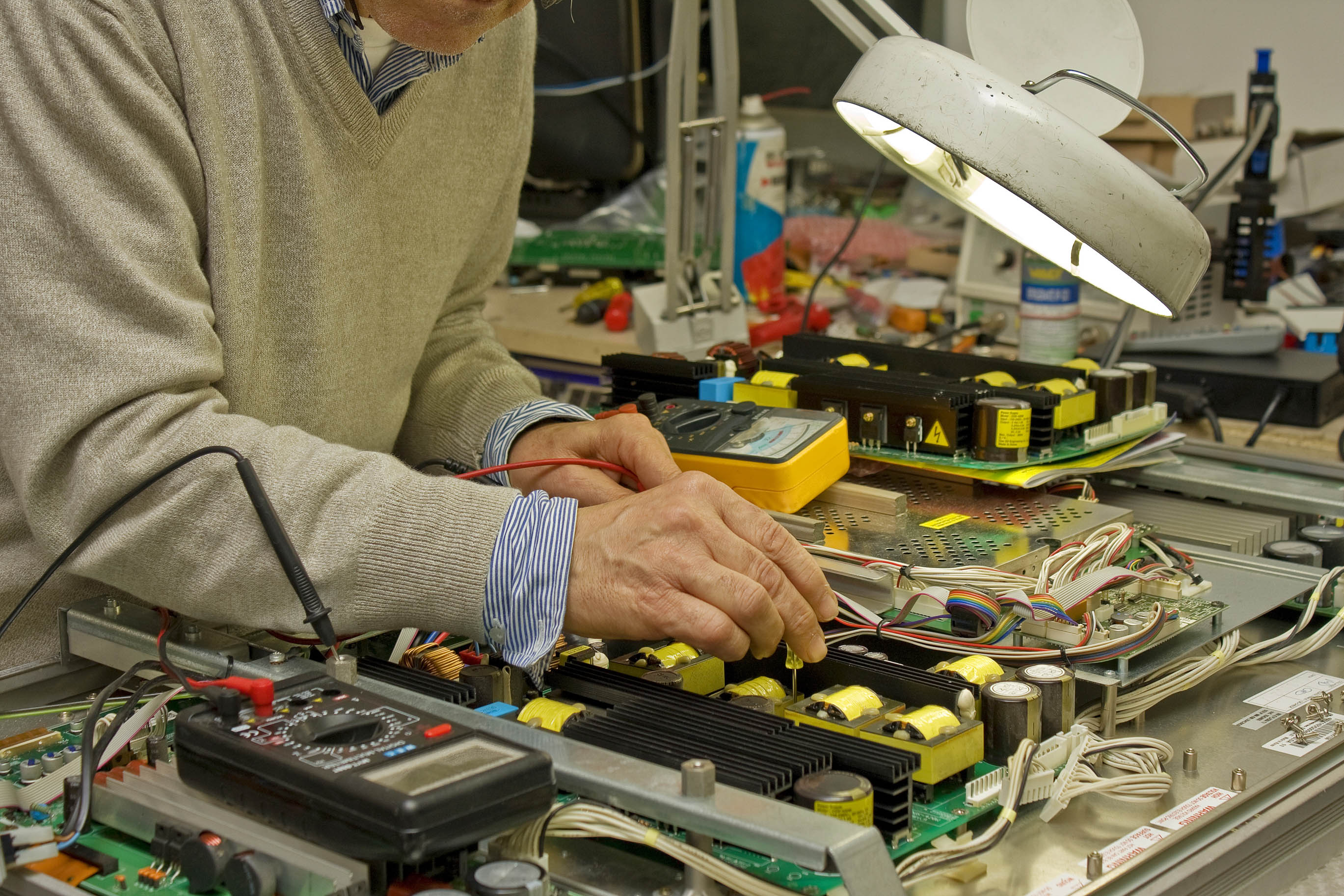

Electrical and Automation Maintenance and Repair

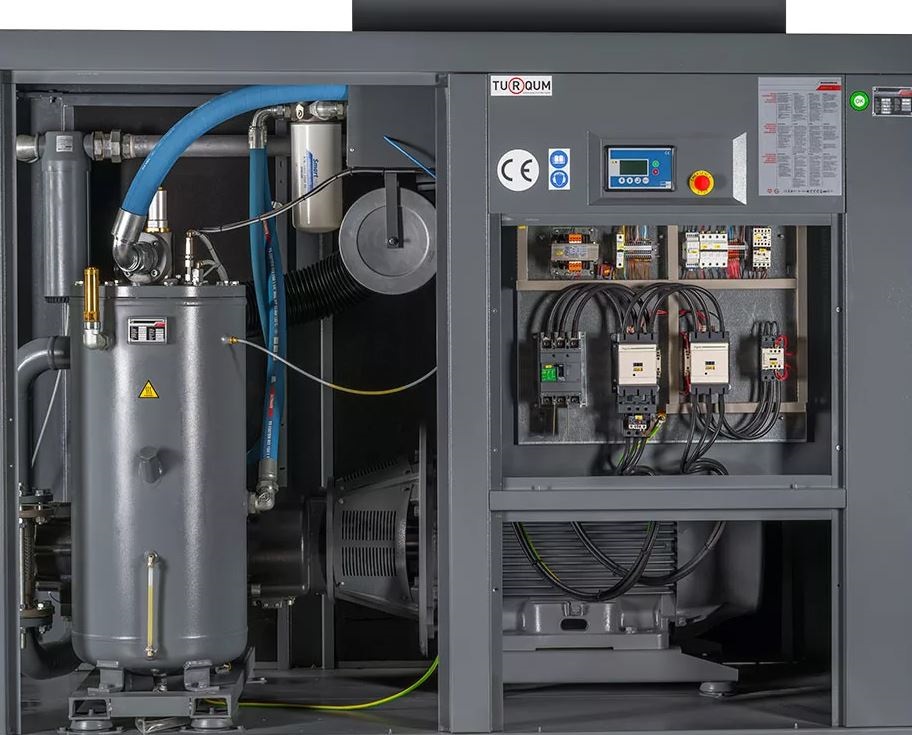

Air Conditioning System

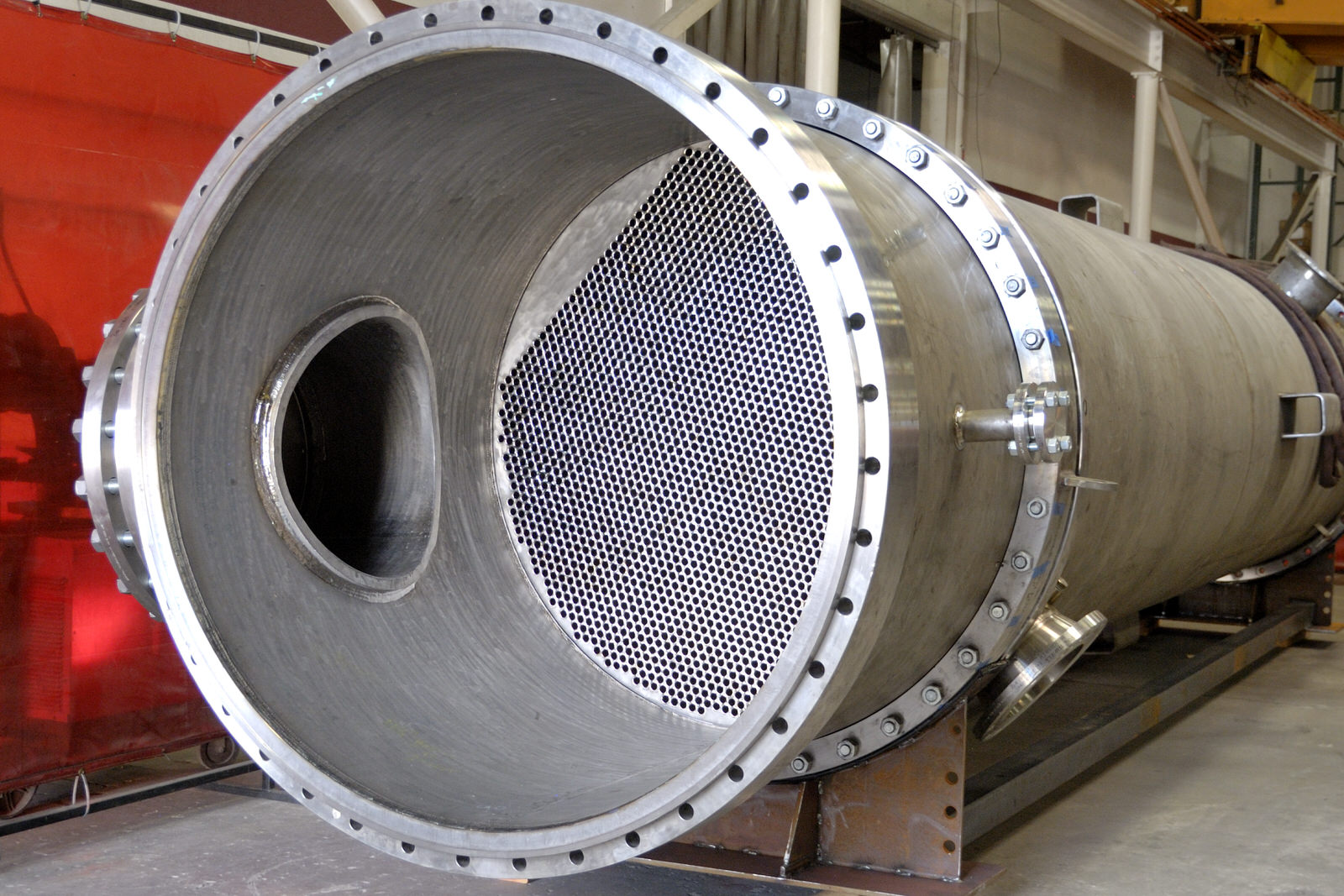

Boiler Services

Workshop Services

Equipment Commissioning

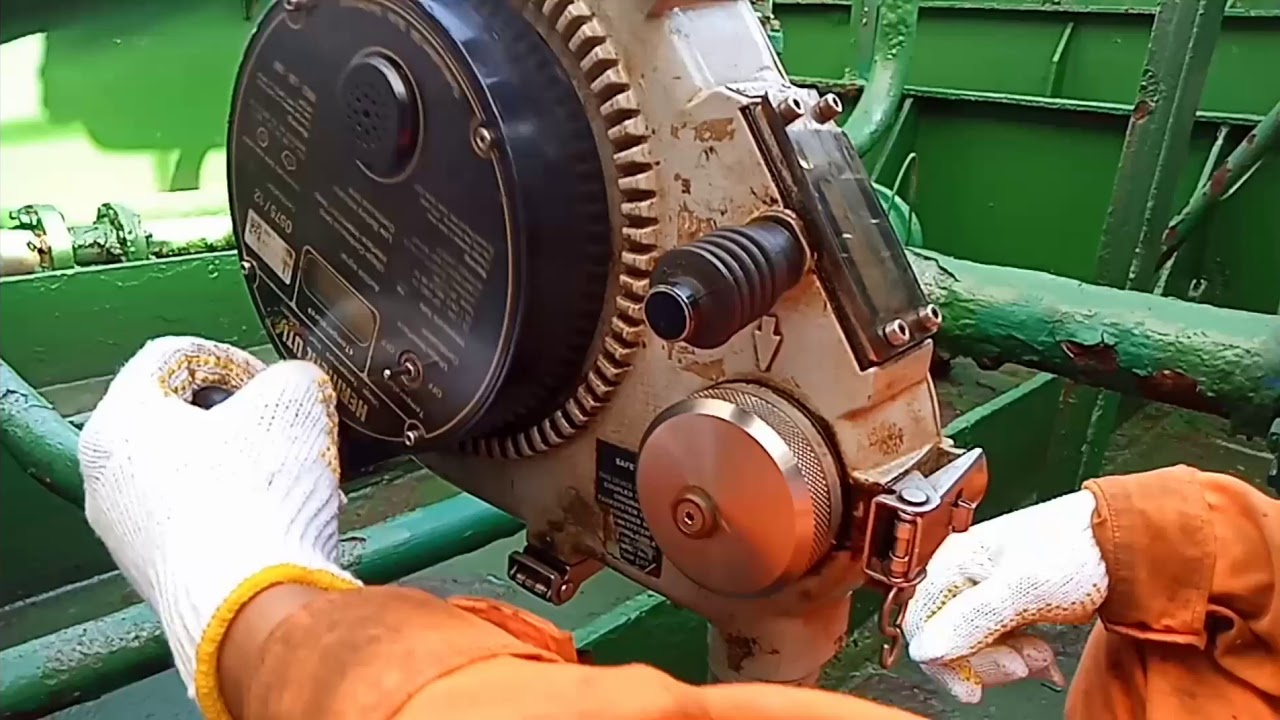

Calibration Services

Calibration Services

Calibration And Certification of 15 Ppm Bilge Alarms Service

Calibration And Certification Of Transmitters Service

Calibration And Certification of Stationary Gas Monitoring Systems For Wbt And Vecs Service

Calibration And Certification of All Models of Gg Stationary O2 Analyzer Service

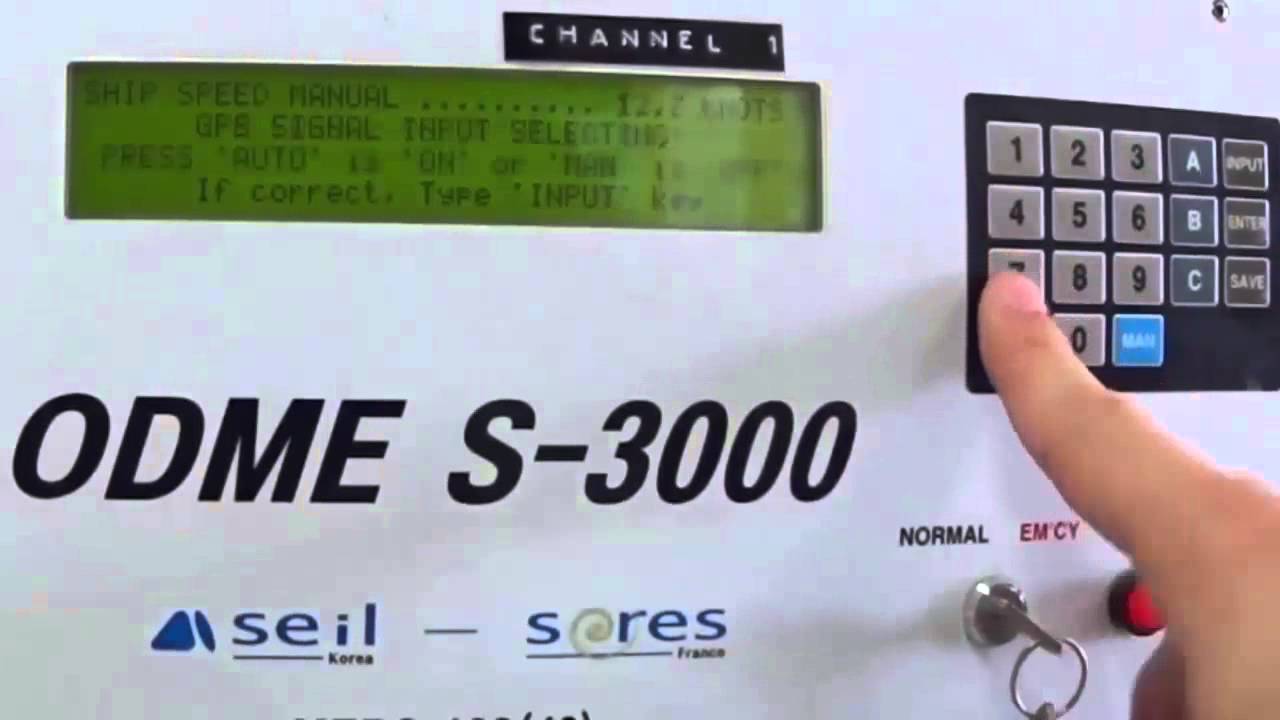

All ODME (Oil Discharge Monitoring and Control System

Service Testing and Certification of Fire Alarm Systems on Board

Calibration and Certification of the Uti Band

Calibration and Certification of Portable and Personal Gas Detectors

Calibration and Certification of Alcohol Detectors

- Ship Emergency Service

- Safety Equipment

- Contact

No Member Login!

Become a Member to Create a Support Request and Learn the Status of Your Service.

New User

- Homepage

- Corporate

-

Technical Service

- Mechanical Services

- Engine Overhauling

- Turbocharging Services

- Electrical and Automation Maintenance and Repair

- Air Conditioning System

- Boiler Services

- Workshop Services

- Equipment Commissioning

-

Calibration Services

- Calibration Services

- Calibration And Certification of 15 Ppm Bilge Alarms Service

- Calibration And Certification Of Transmitters Service

- Calibration And Certification of Stationary Gas Monitoring Systems For Wbt And Vecs Service

- Calibration And Certification of All Models of Gg Stationary O2 Analyzer Service

- All ODME (Oil Discharge Monitoring and Control System

- Service Testing and Certification of Fire Alarm Systems on Board

- Calibration and Certification of the Uti Band

- Calibration and Certification of Portable and Personal Gas Detectors

- Calibration and Certification of Alcohol Detectors

- Ship Emergency Service

- Safety Equipment

- Contact